Products

When Quality Matters

Why Choose Us

Key Advantages

Uniform Wall Thickness

FormTech is specialized in producing porcelain dipping formers for NBR and NR glove manufacturers. Our unique design and manufacturing process generates a uniform wall thickness which is the decisive factor in the even temperature distribution of an entire glove former. It is proven that the wall thickness, unlike the former weight, is the best way to determine the performance of a former.

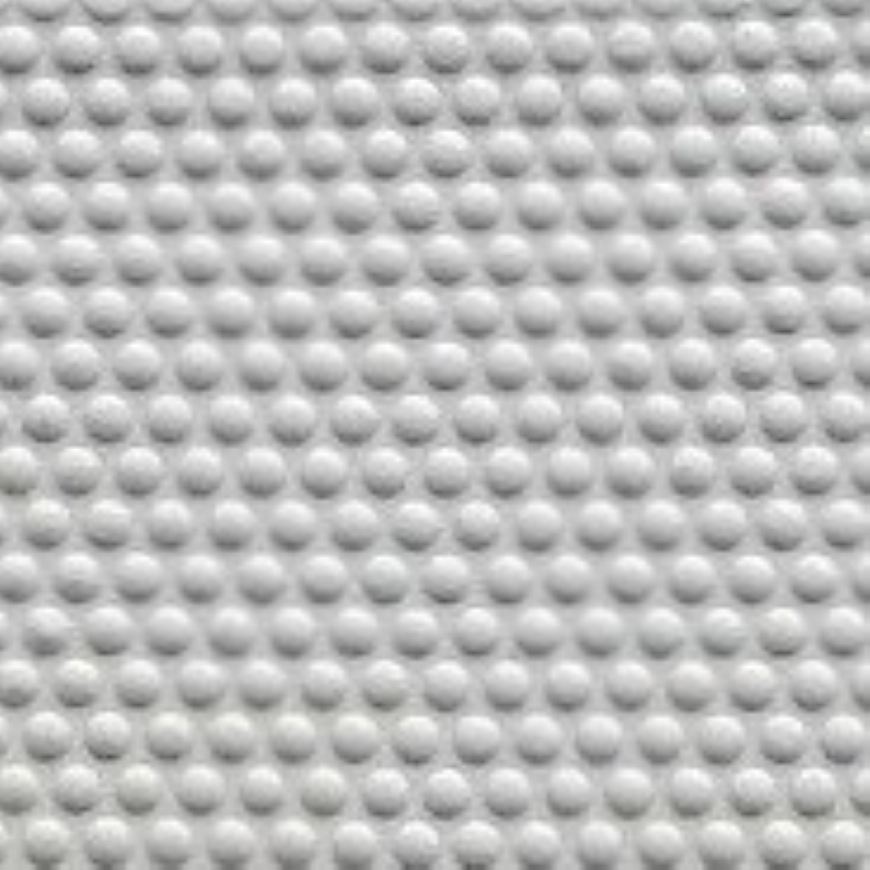

FormTech Coatings

Our coatings are in-house developments to improve the physical properties of the formers and provide the best-performing surfaces for our customer’s dipping process. The automated application ensures constancy throughout.

Our Products

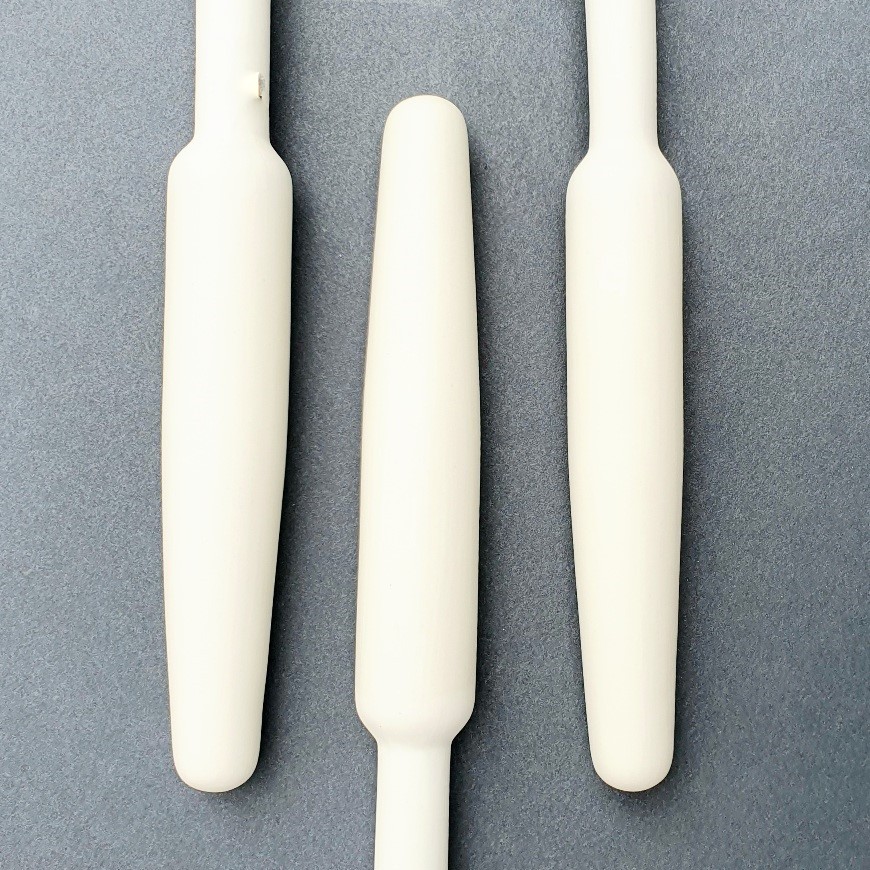

Examination Glove Formers

Our highly automated manufacturing process ensures examination formers of consistently high quality.

Additionally, we offer customised solutions that suit our clients’ needs. These include different texture grades for finger, palm, or full-body, sandblast or spray-on application, and a selection of coatings.

Long Lifespan!

FormTech formers are known for their high quality and long lifespan.

The examination formers follow European and US standards.

Energy Saver

Introduced in 2016, FormTech’s Energy Saver formers have fast gained acceptance and popularity amongst our customers.

In fact, the majority of our examination formers produced and sold by FormTech are Energy Saver formers.

Save Energy, Save Cost

With smart energy management, glove manufacturers can prepare themselves for the future by reducing the consumption of valuable resources.

FormTech Energy Saver formers are designed to save costs with every dip.

Our lightest former comes close to the weight of a metal former!

Surgical Glove Formers

FormTech mostly produces surgical glove formers that are exclusive to individual customers.

We can provide customised surfaces, textures, patterns, designs and embossments.

Our formers follow all international standards.

All developments in collaboration with our customers are kept strictly confidential!

For the Perfect Fit

We collaborate closely with our customers to produce solutions that precisely address their specifications and requirements.

Tailor-made Products

On special request, FormTech offers selected products for our customers’ research departments, e.g., finger cot moulds, corrosion test rings, and test plates with coatings and textures of their choice.

We also provide all kinds of patterns and specific customised products upon request.

Developed and produced in collaboration with our customers

FormTech Coatings

Our coatings give a glove former additional strength and final surface properties. They are developed by our R&D team to ensure that it is the perfect match for our high-strength porcelain body. In combination with high thermal shock resistance and high corrosion resistance, the right coating is the key to a longer lifespan. Coatings can be matt, glossy or anything in between, which depends on the raw material used. Its micro textures can be flat, smooth, flaky or rough as a result of different application methods.

Our sales department will always help you find the best solution for your glove production.

Coating

SE

E

B

Appearance

- Matt

- Smooth surface

- White color

- Semi-matt

- Smooth surface

- White color

- Mildly shiny

- White color

Benefits

- Low pinhole rate

- High F@B results

- Thin gloves

- Good all-rounder

- Long lifespan

- Good all-rounder

- Long lifespan